PIPING ENGINEERING TRAINING

Contact Advertiser

Get a fresh start every day and gain 1000 times more views with banner!

- Do not pay in advance even for the delivery.

- Try to meet at a safe or public location.

- Check the item BEFORE you buy it.

- Pay only after collecting the item.

Ad-node Tabs

BENEFITS OF TRAINING

What is Piping Engineering course?

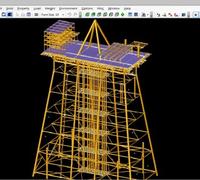

A comprehensive course covering in depth the design of various pressure piping systems including Basic, Piping Design , Piping Engineering , Piping Layout Pipe Stress Analysis ,detailed design and engineering etc. This course also provides design projects per ASME B 31.

Training Schedule: By Request/In Session

Training Method: Classroom/Virtual

Duration: 5 Days

COURSE OBJECTIVE:

The objective of this course is to provide the participants with the fundamentals principles behind the design, construction, Integrity Assessment and operation of both onshore and offshore pipelines.

* Addresses:-

* Lagos: 41, Osolo way Ajao Estate, By 7 & 8 Junction, Off International Airport Road Isolo, Lagos State

* Suite 48 Futeb Plaza, Effurun-Sapele Road, Opposite Refinery road Junction, By Delta Shopping Mall(Shoprite), Effurun/Warri, Delta State

COURSE OUTLINE:-(BASIC)

1. Introduction to Piping fundamentals:

- Differences between pipe and tube. Types of pipe, NPS.

- Piping systems and arrangement.

- Methodology of Pipe size calculations & Pipe material selection

2. Pipe fittings and connections: Tees, elbows, Reducers, Olet, Nipples and Gaskets, Spectacle blinds, couplings, stub-in, unions, plug, and weld caps

3. Pipe fittings and connections: Flanges, types and functions, pressure temperature relationships.

4. Pipe fittings and connections:

- Valves, types and functions. Valve material selections

- Pipe supports and pipe racks

5. Deliverables in piping Engineering and documentations

6. Design Phases: Preliminary, Conceptual, FEED, and Detail.

- P & ID , PFD: Meaning, importance, applications, and limitations

- How to read and interpret P & ID.

- Line numbering philosophy

7. Meaning and applications of Piping & Equipment layout Layout,

- General Arrangement drawings and Piping Isometric drawings.

- Interpreting Piping layout, PGA and Piping Isometric drawings.

8. International standards: ASME, API, ANSI, ASTM and their codes.

- ASME B31.3, B31.4, B31.8, B16.5, B36.10, B36.19.

- ASTM A105, ASTM A106, ASTM 234, etc

9. Grade selection of pipe

- Wall thickness calculations

- Piping material selection and specification

- Piping class and MTO (Material take-off List)

- Valve Data sheets

10. Pipe datapro software applications

ADVANCED:-

1. Introduction to Piping fundamentals:

- Differences between pipe and tube. Types of pipe, NPS.

- Piping systems and arrangement.

- Methodology of Pipe size calculations & Pipe material selection

2. Pipe fittings and connections: Tees, elbows, Reducers, Olet, Nipples and Gaskets, Spectacle blinds, couplings, stub-in, unions, plug, and weld caps

3. Pipe fittings and connections: Flanges, types and functions, pressure temperature relationships.

4. Pipe fittings and connections:

- Valves, types and functions. Valve material selections

- Pipe supports and pipe racks

5. Deliverables in piping Engineering and documentations

6. Design Phases: Preliminary, Conceptual, FEED, and Detail.

- P & ID , PFD: Meaning, importance, applications, and limitations

- How to read and interpret P & ID.

- Line numbering philosophy

7. Meaning and applications of Piping & Equipment layout Layout,

- General Arrangement drawings and Piping Isometric drawings.

- Interpreting Piping layout, PGA and Piping Isometric drawings.

8. International standards: ASME, API, ANSI, ASTM and their codes.

- ASME B31.3, B31.4, B31.8, B16.5, B36.10, B36.19.

- ASTM A105, ASTM A106, ASTM 234, etc

9. Grade selection of pipe

- Wall thickness calculations

- Piping material selection and specification

- Piping class and MTO (Material take-off List)

- Valve Data sheets

10. Pipe datapro software applications

- Pipe stress Analysis reports using CAESAR 2 Software applications (Basic)

11. Pressure vessel design and Analysis reports using PV Elite software applications (Basic)

- PDMS (Equipment & Piping Basic)