PIPING ENGINEERING TRAINING

Contact Advertiser

Get a fresh start every day and gain 1000 times more views with banner!

- Do not pay in advance even for the delivery.

- Try to meet at a safe or public location.

- Check the item BEFORE you buy it.

- Pay only after collecting the item.

Ad-node Tabs

BENEFITS OF TRAINING

What is Piping Engineering all about?

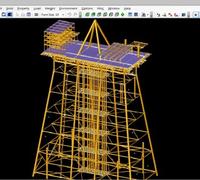

Piping Engineering is a specialized discipline of Mechanical Engineering which covers the design of piping and layout of equipment and process units in chemical, petrochemical or hydrocarbon facilities. Most of the plant facilities in the petrochemical and hydrocarbon industry will use ASME B31

Training Schedule: By Request/In Session

Training Method: Classroom/Virtual

Duration: 5 Days

CLICK HERE TO REGISTER[https:///2348164085555?text=ENQUIRIES]

HOW TO RESERVE A SEAT

* Call/Text/whatsapp your name, phone number, email and course of interest to 08164085555, 09076777762 before training day for seat reservation

COURSE OBJECTIVE:

To address the analytical, physical and numerical modelling techniques used in engineering practice for the design of onshore and offshore pipeline systems.

* Addresses:-

* Lagos: 41, Osolo way Ajao Estate, By 7 & 8 Junction, Off International Airport Road Isolo, Lagos State

* Suite 48 Futeb Plaza, Effurun-Sapele Road, Opposite Refinery road Junction, By Delta Shopping Mall(Shoprite), Effurun/Warri, Delta State

COURSE OUTLINE:-(BASIC)

1. Introduction to Piping fundamentals:

- Differences between pipe and tube. Types of pipe, NPS.

- Piping systems and arrangement.

- Methodology of Pipe size calculations & Pipe material selection

2. Pipe fittings and connections: Tees, elbows, Reducers, Olet, Nipples and Gaskets, Spectacle blinds, couplings, stub-in, unions, plug, and weld caps

3. Pipe fittings and connections: Flanges, types and functions, pressure temperature relationships.

4. Pipe fittings and connections:

- Valves, types and functions. Valve material selections

- Pipe supports and pipe racks

5. Deliverables in piping Engineering and documentations

6. Design Phases: Preliminary, Conceptual, FEED, and Detail.

- P & ID , PFD: Meaning, importance, applications, and limitations

- How to read and interpret P & ID.

- Line numbering philosophy

7. Meaning and applications of Piping & Equipment layout Layout,

- General Arrangement drawings and Piping Isometric drawings.

- Interpreting Piping layout, PGA and Piping Isometric drawings.

8. International standards: ASME, API, ANSI, ASTM and their codes.

- ASME B31.3, B31.4, B31.8, B16.5, B36.10, B36.19.

- ASTM A105, ASTM A106, ASTM 234, etc

9. Grade selection of pipe

- Wall thickness calculations

- Piping material selection and specification

- Piping class and MTO (Material take-off List)

- Valve Data sheets

10. Pipe datapro software applications

ADVANCED:-

1. Introduction to Piping fundamentals:

- Differences between pipe and tube. Types of pipe, NPS.

- Piping systems and arrangement.

- Methodology of Pipe size calculations & Pipe material selection

2. Pipe fittings and connections: Tees, elbows, Reducers, Olet, Nipples and Gaskets, Spectacle blinds, couplings, stub-in, unions, plug, and weld caps

3. Pipe fittings and connections: Flanges, types and functions, pressure temperature relationships.

4. Pipe fittings and connections:

- Valves, types and functions. Valve material selections

- Pipe supports and pipe racks

5. Deliverables in piping Engineering and documentations

6. Design Phases: Preliminary, Conceptual, FEED, and Detail.

- P & ID , PFD: Meaning, importance, applications, and limitations

- How to read and interpret P & ID.

- Line numbering philosophy

7. Meaning and applications of Piping & Equipment layout Layout,

- General Arrangement drawings and Piping Isometric drawings.

- Interpreting Piping layout, PGA and Piping Isometric drawings.

8. International standards: ASME, API, ANSI, ASTM and their codes.

- ASME B31.3, B31.4, B31.8, B16.5, B36.10, B36.19.

- ASTM A105, ASTM A106, ASTM 234, etc

9. Grade selection of pipe

- Wall thickness calculations

- Piping material selection and specification

- Piping class and MTO (Material take-off List)

- Valve Data sheets

10. Pipe datapro software applications

- Pipe stress Analysis reports using CAESAR 2 Software applications (Basic)

11. Pressure vessel design and Analysis reports using PV Elite software applications (Basic)

- PDMS (Equipment & Piping Basic)