Professional Roof Panel Roll Forming Machine / Equipment For Civil House

Contact Advertiser

Get a fresh start every day and gain 1000 times more views with banner!

- Do not pay in advance even for the delivery.

- Try to meet at a safe or public location.

- Check the item BEFORE you buy it.

- Pay only after collecting the item.

Ad-node Tabs

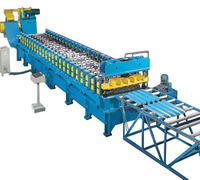

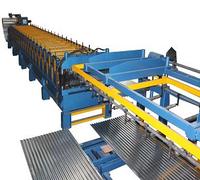

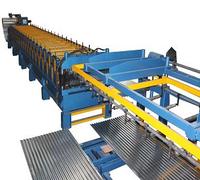

High Quality Corrugated Long Span Roofing Sheet Roll Forming Machine for Civil House

Introduction

We are supplying all kinds of metal roll forming machines with high quality, such as trapezoid /wave profile roof & wall panel roll forming machine, step roofing tile roll forming machine, C & Z purlin roll forming machine, floor deck roll forming machine, C stud & U track roll forming machine, roller shutter door slat roll forming machine, highway guardrail roll forming machine, ridge cap roll forming machine, roof rain gutter roll forming machine, water downspout roll forming machine and so on. The advertised roll forming machine here is an advanced metal rollformer, which is making prepainted long span roofing sheets at a high speed.

Professional Roof Panel Roll Forming Machine / Equipment For Civil House

Technical Parameters (some parameters depend on the final design)

1 Machine name: long span roof sheets making machine

2 Machine dimension (mm) 9000*1600*1500; Total wight (Kg) 9500

3 Forming steps 20; Forming speed (m/min) 15-20

4 Main driving motor power(Kw) 7.5; Diameter of rolling shaft (mm) 72

5 Hydraulic pressure(MPa) 10; Electric condition 380V/3Phase/ 50HZ

6 Power for hydraulic decoiler(Kw) 5.5 x 2; Decoiler max capacity (Kgs) 5000

7 Control system Mitsubishi PLC

8 Raw material thickness (mm) 0.3-0.7; Effective width(mm) 1000; Material width(mm) 1200

Main Description

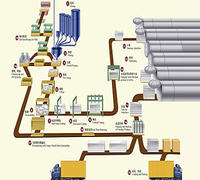

1 Automatic hydraulic uncoiler(according the machine and your requirement)

(1). Loading Capacity: 5-10 tons; (2). Main motor: 5.5 KW x 2; (3). Coil Width:Max: 1250mm

2 Entry Bench: Guiding the raw material into the roll forming machine smoothly

3 Feeding Section with guide: Easily for the raw material entry

4 Main roll former machine: Forming the panel according your requirement

5 PLC control system: Automatically control the quantity of sheet, cutting length

6 Cutting blade: Cutting the panel automatically

7 Product Rack: Can adjustable according the length of the panel

8 Pressing device: Pressing the panel automatically

9 Mesh safety cover on roll former (optional): For safety

Feature:

1. Cutter Material: Cr12 mould steel with heating treatment

2. Shaft Material: #45 steel with quenching treatment

3. Roller Material: #45 steel with quenching treatment, then coated with hard chrome

4. Have fashionable, nice appearance and durable

5. Delivery time: around 60 working days

6. Full automatic production

7. All our machines are designed and manufactured according to customers' requirement

We are supplying all kinds of oven baked aluminium roofing sheets making machines, such as box prfiled longspan metral roofing sheet corrugating machine, normal steptile roof sheet making machine, metcopo step tile roof sheet corrugation machine, cameroon aluzinc roof sheet making machine, ridge cap manufacturing machine and so on. If you want to get more details about this Professional Roof Panel Roll Forming Machine / Equipment For Civil House, please contact us by the following information!

Email: [email protected]

Mobile: +0086 158 6814 2550