MTW Series Trapezoid Mill

Contact Advertiser

Get a fresh start every day and gain 1000 times more views with banner!

- Do not pay in advance even for the delivery.

- Try to meet at a safe or public location.

- Check the item BEFORE you buy it.

- Pay only after collecting the item.

Ad-node Tabs

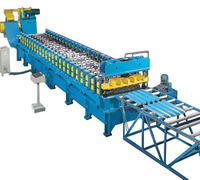

Our company recently introduced the latest grinding equipment MTW Series European Trapezium Mill with international advanced technology. The MTW Series Trapezoid Mill adopts many latest patents, such as cone gears transmission, inner thin oil lubrication system and arch wind flow and so on.

Features of MTW Series Trapezoid Mill

1. Cone gears transmission: additional reducer is needed for a traditional mill, driving the main draft through sleeve pipe, which is difficult in installation and has loud noise and low efficiency. The MTW series European trapezium mill use cone gears transmission, which is compact in structure, convenient and prompt to install and adjust. It is helpful for improving efficiency.

2. Inner thin oil lubrication system: lubrication pattern of traditional mills is grease lubrication, which is of more resistance, high temperature and short life span; the MTW series European trapezium mill adopts inner oil pump. No additional oil pump or lubrication plant is needed for the lubrication of the main draft and cone gear draft.

3. Arch air channel: mill air channel of traditional mills are of straight type. This structure has disadvantages of resistance caused by air flow impacting air channel plat, energy will loss by mutual impact of air molecules. Air channel of the MTW series European trapezium mill adopts the curved surface channel, in which, air flow is able to enter smoothly with little resistance; the inner outlet is helpful for scatter of materials and can reduce material stuck.

4. Blade on the curved surface is changeable: blade of traditional mill is wearable, and blade is a wholesome one, which should be changed totally and is material wasting and will prolong stop time. Blade of the MTW series European trapezium mill is of high abrasive alloy material, long life span; which changing, only blade is necessary to be changed, which can greatly improve material utilizing ratio. Besides, with traditional flat blade, materials are piped to one layer, which is possible to damage center of roller ring of the roller, while curved blade is able to guide materials to a vertical surface and powder can be milled in up-middle-down part of the roller and mills evenly, which is able to increase working area and capacity.

5. Separated cyclone dust collector: separated structure is adopted between the inner barrel and mixed air powder, which is able to improve efficiency and accuracy of powder selection.

6. Wind inlet scroll casing: for traditional mill, inner side of the inner observing door protrudes, which is not on the same surface with the wind inlet scroll casting. Thus, there will be eddy effect, and energy consumption of the whole system will increase a lot, while those of the MTW series are on the same surface, which is able to avoid eddy effect.

7. Beautiful appearance: while adopting advanced structure inside the mill, we adopt beautiful arch structure design, which will make the mill beautiful and intelligent.

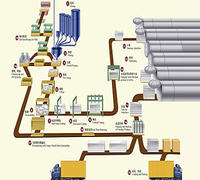

Application of MTW Series Trapezoid Mill

The MTW series European trapezium mill is mainly used to process power of metallurgy, chemicals, ores and other ore products, which is able to mill quartz, feldspar, calcite, talcum, barite, fluorite, rare earth, marble, ceramics, bauxite, manganese, iron, copper, rock phosphate, iron oxide red, zircon sand, slag, slag , cement clinker, activated carbon, dolomite, granite, garnet, iron oxide yellow, fertilizer, compound fertilizer, fly ash, bituminous coal, coke, lignite, Ling U.S. sand, chromium oxide green, gold, red mud, clay, Kaolin, coke, coal gangue, porcelain clay, kyanite, fluorspar, bentonite, medical stone rhyolite, diabase, leaf wax rock, shale, purple rock, Diego rock, basalt, gypsum, graphite, silicon carbide , insulation materials, whose Mohs hardness is under 9th grade, and various non-flammable non-explosive ore materials with moisture below 6%.

For more information, please visit:

http://www.mineralcrushers.org/mtw-series-trapezoid-mill/

Contact: Cloris Fang

Email: [email protected]

Web: http://www.mineralcrushers.org/

http://www.trituradoramovil.com.co

http://www.concasseur-mobile.fr

http://www.ikefid.com