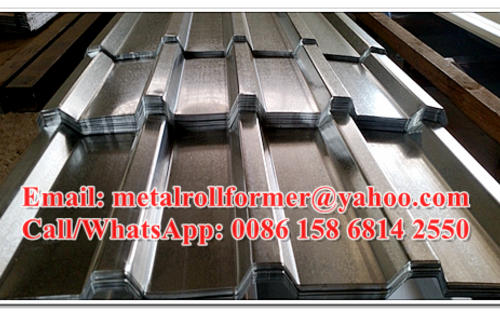

Strong Corrugated Sheet Roll Forming Machine With Mitsubishi PLC Control from Japan

Contact Advertiser

Get a fresh start every day and gain 1000 times more views with banner!

- Do not pay in advance even for the delivery.

- Try to meet at a safe or public location.

- Check the item BEFORE you buy it.

- Pay only after collecting the item.

Ad-node Tabs

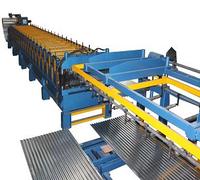

Strong Corrugated Longspan Roofing Sheet Roll Forming Machine for Voltage 380V or 415V

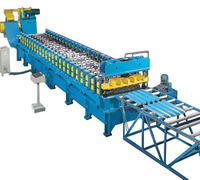

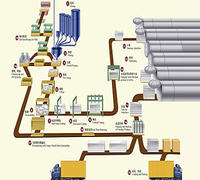

Working flow of Corrugated Roof Sheet Production Line

Decoiling- Sheet Guiding - Rollforming - Post-cutting - Finished Roof Sheet on Supporters

Machine Components of Aluminium Roof Sheet Corrugating Machine

De-coiler 1 set

Roll Forming System 1 set

Cutting Device 1 set

PLC Control Box 1 set

Hydraulic Pump Station 1 set

Product supportting Tables 1 set

Technical description Aluminium Roof Sheet Corrugating Machine

A Manual decoiler (automatic decoiler is optional)

Max.capacity: 5000kg; Coil inner-diameter: 508mm; Out Diameter: 1000 mm

B Roll-Forming System

Material thickness: 0.4-0.7mm

Feeding width and effective width depens on profile drawing

Rolling Steps: around 20 sets; Coated Chrome Thickness: 0.05 mm

Roller Material: 45# steel with quenching treatment, then coated with chrome

Shaft Material: 45# steel with quenching treatment; Shaft Diameter:72mm

Voltage: 380V/50Hz/3Phase; Corrugating Speed: 15-20meters/min; C Cutting Device

It adopts hydraulic drive and automatic location to decide the dimention and cut the target products.

Match equipment : one set of cutting tool, one hydraulic tank ,one cutter machine.

Cutting length tolerance: +-2mm; Cutting tool material: GCr12 with quenched treatment 60-62degC; Power of the oil pump: 3kw; Hydraulic oil :40#

D Control System

It adopts Taida PLC to control. The target piece length is adjustable and digit of it can be adjusted; Computed mode has two modes: automatic and manual one.

Type: PLC Frequency Control System with touching screen; PLC Brand: Mitsubishi; Encoder Brand: Omron; Length Error:+-2mm; Transducer: Mitsubishi

E Output Table

It is simple to be used to support finished products. Length: 1.5 meters for each

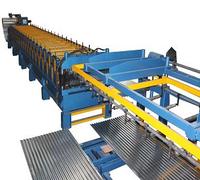

We are supplying all kinds of oven baked aluminium roofing sheets making machines, such as box prfiled longspan metral roofing sheet corrugating machine, normal steptile roof sheet making machine, metcopo step tile roof sheet corrugation machine, cameroon aluzinc roof sheet making machine, ridge cap manufacturing machine and so on. If you want to get more details about this Strong Corrugated Sheet Roll Forming Machine With Mitsubishi PLC Control from Japan, please contact us by the following information!

Email: [email protected]

Mobile: +0086 158 6814 2550