Raymond Mill

Contact Advertiser

Get a fresh start every day and gain 1000 times more views with banner!

- Do not pay in advance even for the delivery.

- Try to meet at a safe or public location.

- Check the item BEFORE you buy it.

- Pay only after collecting the item.

Ad-node Tabs

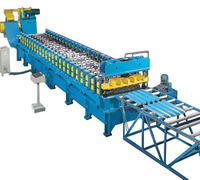

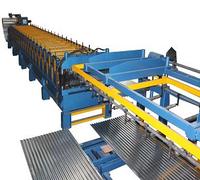

Raymond mill is the first-generation of medium-speeding tilting milling equipment which adopts the technology we imported from United States and transformed. Fineness of product ranges from 0.613mm to 0.44mm. Raymond Mill is the ideal equipment for grinding industries, especially suitable for small and medium enterprises.

Features of Raymond Mill

1. Raymond mill adopts a vertical structure, which is small in working area, and easy to be allocated as a set, each process from bulk material to powder product can be a independent production system.

2. Finished powder has even fineness, a screen passing ratio of 99%, which is not possible for other mill equipment.

3. Drive unit is the closely sealed gear box and belt wheel, which is stable in transmission and reliable in operation.

4. Key parts of the Raymond mill are all high-quality style, wearable parts are of high-performance abrasion resistant material. The whole equipment has perfect performance, reliable operation. Blade frame of the main engine is always contacting with materials. Thus the blade frame is composed of two parts, while bottom frame is worn, discharge is continuous and changeable.

5. Electrical system adopts contracted control, grinding workshop can basically run without people, and is convenient to maintain.

6. Less dust and lower noise.

Application of Raymond Mill

Raymond mill is widely used in metallurgy, construction materials, chemicals, ores to produce powder, which is suitable for non-flammable and non-explosive ores with Mohs hardness below 9.3, humidity below 6%, such as Gypsum, talc, calcite, limestone, marble and feldspar, barite, dolomite, granite, kaolin, stone, bauxite, iron oxide red, iron ore and so on.

Working Principle of Raymond Mill

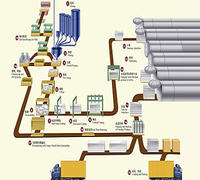

Raymond Mill transmits the motor torque to the main axis through pulley or reducer. When roller rotates around ring, itself rotates, either. At the same time, the shovel scoops up the material, send to the space between ring and roller to accomplish the grinding. The rise of power and air flow in the classifier, the powder drops spirally along the tube wall. In the locking powder place, air begins to form rising cyclone and are brought back to blower. The whole set’s airflow system is closely sealed up and circulated under condition of negative and positive pressure.

For more information, please visit:

http://www.kefid-crusher.com/Grinding-Mill/Raymond-Mill.html

Contact: Cloris Fang

Email: [email protected]

Web: http://www.kefid-crusher.com

http://www.mineralcrushers.org/

http://www.trituradoramovil.com.co

http://www.concasseur-mobile.fr

http://www.ikefid.com