Steel / Aluminium Roof Panel Roll Forming Machine 380V / 50HZ

Contact Advertiser

Get a fresh start every day and gain 1000 times more views with banner!

- Do not pay in advance even for the delivery.

- Try to meet at a safe or public location.

- Check the item BEFORE you buy it.

- Pay only after collecting the item.

Ad-node Tabs

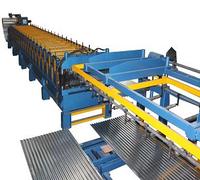

Steel and Aluminium Roofing Sheet Rolling Machine with 20 Sets of Chrome Coated Rolling Stations

Components of Roof Sheet Cold Rollforming Production line

- Uncoiler with two supporters

- Coil sheet direction adjusting equipment

- Filming device

- Main roll forming system

- Post- cutting device

- Hydraulic station

- PLC control System

- Support tables

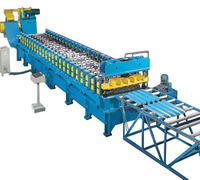

Technical Specifications of Steel Roof Sheet Cold Rollforming Production line

1 Suitable raw materials Color & galvanised steel plate/aluminium plate, aluzinc

2 Spec. of raw materials 1200mm wide; 0.3-0.7mm thick

3 Rollers quantity 20 sets

4 Machine dimensions 9.5 x 1.6 x 1.5 meters

5 Motor power 7.5 + 2.2kw

6 Roller material high grade 45# steel (plated with chrome on surface)

7 Production Speed 15-20m/min

8 Diameter of the rolling shaft F72mm

9 Voltage 380V/50HZ/3Phases

10 Material of the cutting blades Cr12 mould steel

11 Hydraulic 40#

12 Sheet length tolerance +-1mm

13 Control System Mitsubishi PLC, inverter and touching screen

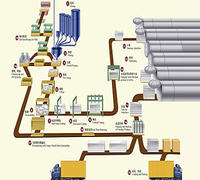

Working flow:

Decoiling the sheet- - - Guiding the sheet- - - Film covering- - - Roll forming- - - Measuring the length- - - Cutting the panel- - - Finished panels to the supporters

Material Information for Roof Sheets Machine Manufacturing:

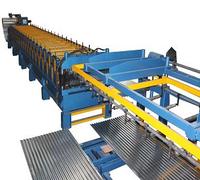

* Roller: High grade No. 45 forged steel, plated with 0.05mm hard chrome on the surface of rollers

* Active shaft material: High grade No. 45 carbon wrought steel of diameter 75mm.

* Cutting blade: Cr12 mould steel with quenching treatment.

Steel / Aluminium Roof Panel Roll Forming Machine 380V / 50HZ

Competitive Advantages

1. Professional team for design, manufacturing and quality control

2. Customized solution available

3. ISO 9001:2008, CE, SONCAP certification

4. Mitsubishi PLC (Siemens available)

5. One year free warranty

6. Low machine cost, high quality and easy operation

After Service:

The finished machine will be tested and inspected in the workshop before delivery. If customer requires, we can send our technician to customer's site to do the installation, commission and trainning service.

We are supplying all kinds of oven baked aluminium roofing sheets making machines, such as box prfiled longspan metral roofing sheet corrugating machine, normal steptile roof sheet making machine, metcopo step tile roof sheet corrugation machine, cameroon aluzinc roof sheet making machine, ridge cap manufacturing machine and so on. If you want to get more details about this Steel / Aluminium Roof Panel Roll Forming Machine 380V / 50HZ, please contact us by the following information!

Email: [email protected]

Mobile: +0086 158 6814 2550