QT4-25 Semi-Automatic Brick Machine

Contact Advertiser

Get a fresh start every day and gain 1000 times more views with banner!

- Do not pay in advance even for the delivery.

- Try to meet at a safe or public location.

- Check the item BEFORE you buy it.

- Pay only after collecting the item.

Ad-node Tabs

QT4-25 Semi-Automatic Brick Machine

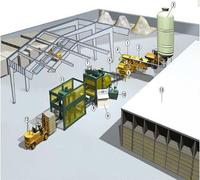

Descriptions of QT4-25 Semi-Automatic Brick Machine:

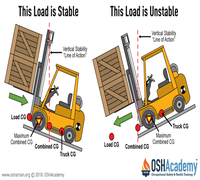

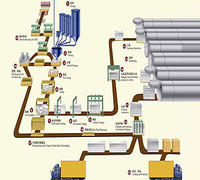

(1) It is reasonable in design and compact in structure. For this machine, a programmable controller is adopted so that it can achieve directional librating, converter braking and quick eliminating energy consumption. Additionally, it is no need manual supplying the plates so that the labor intension can be decreased largely.

(2) Its pressing from the top and bottom, and librating and tamping forcefully is specially suitable to produce the high-intensity blocks, which can be piled up (threet o five layers) immediately after the shaping.

(3) It is of multi-purpose. With different moulds, different shapes and specifications of wall blocks can be produced.

Technical Parameters of QT4-25 Semi-Automatic Brick Machine:

| Type | Production Per Mould | Production Per Shift | Cycle Time | Vibrating Force | Pallet Size | Dimensions |

| QT4-25 |

4pcs/mould 390×190×190mm |

4,000 pcs 390×190×190mm |

25-35 seconds | 50 KN | 880×540mm |

4,500×3,000× 2,500mm |

|

12pcs/mould 240×115×90mm |

12,000 pcs 240×115×90mm |

25-35 seconds | 50KN | 880×540mm |

4,500×3,000× 2,500mm |

Main Features of QT4-25 Semi-Automatic Brick Machine:

1) Classic vibration mode, particularly suitable for production of high-strength blocks, such as standard bricks. Short molding cycles, and higher efficiency.

1) Vibration machine for efficient vibrator, exciting force powerful, the density effect of better products.

2) Forming large area, can produce a variety of cement products, a wide range of production.

3) Compulsory mechanical positioning, infantry expected rapid, uniform and manufactures precision, consistency, good.

4) PLC automatic control systems, interactive user interface, the control system, security configuration logic control, production procedures and fault diagnosis display.

5) The low cost of production, raw materials, make full use of sand, stone powder, flour, coal ash, slag, and other residue.